Our integrated layout facilitates an improved efficiency of materials transfer, production process and product quality from painting to interior installation and final inspection.

The facilities in our product manufacturing process are designed with advanced technology and an integrated system.

Our scientists are facilitated by the latest technology in our R&D lab to thoroughly develop battery prototypes with real-world data as its foundation to minimize the prototype-commercial transition risk.

The arrangement of our warehouses is based on the production planning, inventory control for the production process, and the storage safety factors (according to the materials characterization) with supply chain efficiency as our key objective.

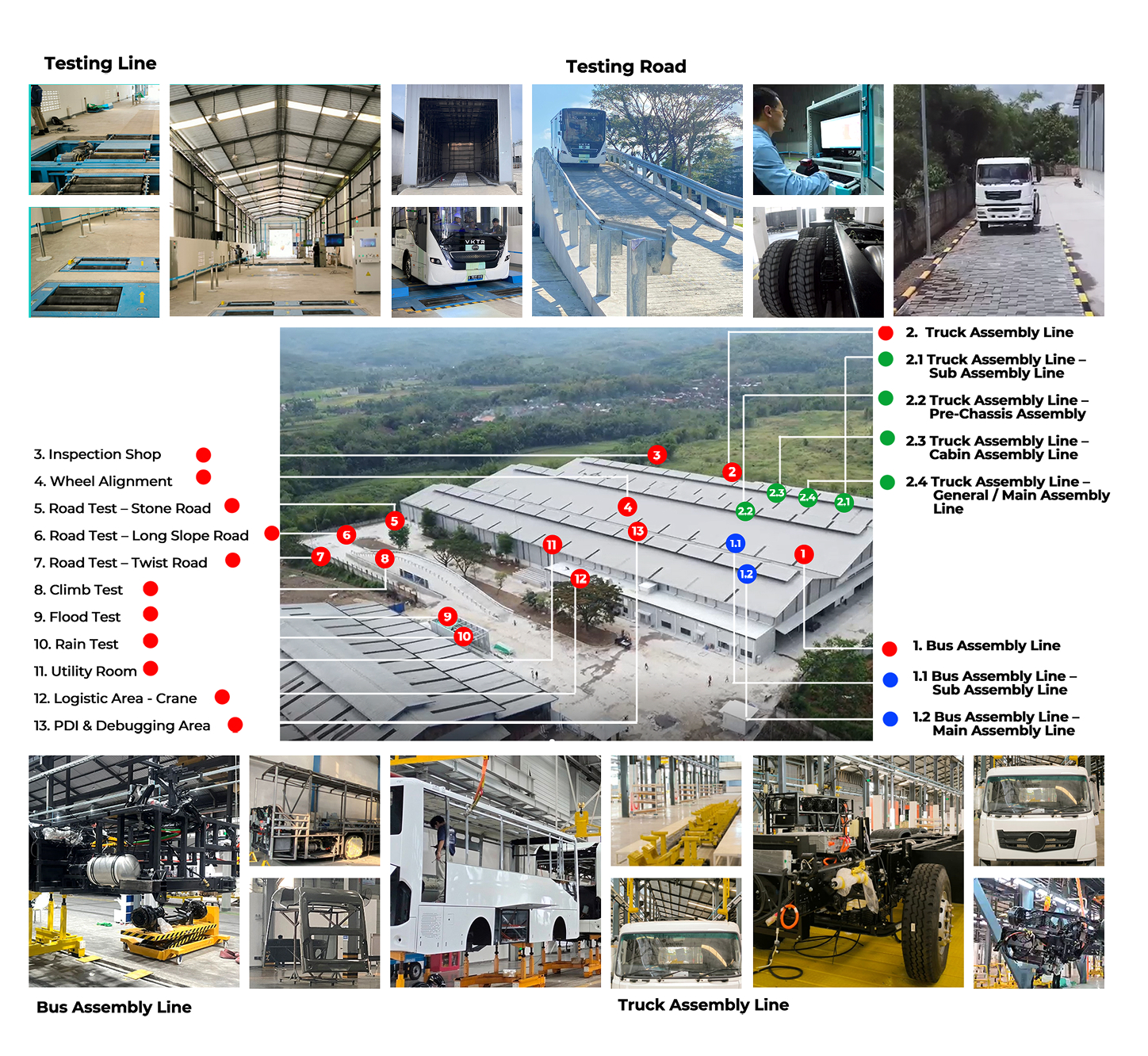

Assembly Plant

In 2024, PT VKTR Teknologi Mobilitas Tbk, through its subsidiary PT VKTR Sakti Industries (VKTS), operated a commercial electric vehicle assembly facility in Magelang based on the Completely Knocked Down (CKD) system and a production capacity of up to 3,000 units per year. One of the key products assembled at this facility is the 12-meter electric bus, which has fulfilled the Local Content (TKDN) requirement more than 40%. Built in collaboration with strategic partners and academic institutions, the facility supports the development of Indonesia’s national electric vehicle industry.

The facility is equipped with modern manufacturing systems and equipment, including bus and truck assembly lines, sub-assembly areas for front & rear axles, leaf springs, and chassis, as well as slat chain conveyors and rotary systems to move chassis to the general assembly line. To ensure quality and safety, the facility also includes a Shower Room, Battery Station, Truck Sub Assembly Line, Wheel Alignment, and an Inspection Room, enabling comprehensive testing before vehicle deployment. This facility strengthens VKTR’s role as a pioneer in CKD-based electric vehicles in Indonesia while also enhancing operational efficiency and the national EV industry’s competitiveness.